| “This site contains affiliate links for which OEMDTC may be compensated” |

June 18, 2019 NHTSA CAMPAIGN NUMBER: 19V467000

If the vehicle’s turning radius is increased, there is an increased risk of a crash.

NHTSA Campaign Number: 19V467

Manufacturer Isuzu Technical Center of America, Inc.

Technical Center of America, Inc.

Components STEERING

Potential Number of Units Affected 3,851

Summary

Isuzu Technical Center of America, Inc. (Isuzu

Technical Center of America, Inc. (Isuzu ) is recalling certain 2018-2020 FTR and Chevrolet

) is recalling certain 2018-2020 FTR and Chevrolet 6500XD vehicles. The jam nut for the steering stopper bolt on the left front knuckle may loosen and allow the bolt to back away from the steering knuckle, increasing the turning radius of the vehicle in a left turn.

6500XD vehicles. The jam nut for the steering stopper bolt on the left front knuckle may loosen and allow the bolt to back away from the steering knuckle, increasing the turning radius of the vehicle in a left turn.

Remedy

Isuzu will notify owners, and dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt, free of charge. The recall began July 19, 2019. Owners may contact Isuzu

will notify owners, and dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt, free of charge. The recall began July 19, 2019. Owners may contact Isuzu customer service at 1-866-441-9638, GM owners may contact GM customer service at 1-800-862-4389. Isuzu

customer service at 1-866-441-9638, GM owners may contact GM customer service at 1-800-862-4389. Isuzu ’s number for this recall is V1902.

’s number for this recall is V1902.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Isuzu Truck has a Recall

BULLETIN NUMBER:

CB19-E-001

ISSUE DATE:

JULY 2019

GROUP:

SUSPENSION & STEERING

IMPORTANT SAFETY RECALL

FTR STEERING STOP JAM NUT REPLACEMENT – 19V-467

(Transport Canada 2019-306)

AFFECTED VEHICLES

- 2018-2020MY Isuzu

FTR Vehicles Wholesaled Before June 19, 2019

FTR Vehicles Wholesaled Before June 19, 2019

INFORMATION

CONDITION

Isuzu Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in 2018, 2019 and 2020 model year FTR vehicles wholesaled before June 19, 2019. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in 2018, 2019 and 2020 model year FTR vehicles wholesaled before June 19, 2019. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

CORRECTION

Isuzu dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

VEHICLES INVOLVED

Involved are 2018, 2019 and 2020 model year FTR vehicles wholesaled before June 19, 2019.

NOTE: It is not necessary to open a TAL case or generate a health report in order to submit a warranty claim.

Important: Dealers are to confirm vehicle eligibility prior to beginning repairs by using the Isuzu Vehicle Inquiry System (IVIS).

Vehicle Inquiry System (IVIS).

For dealers with involved vehicles, a report of involved vehicles containing the complete vehicle identification number has been or will be provided. Dealers will not have a report available if they have no involved vehicles currently assigned.

PARTS INFORMATION

An initial supply of jam nuts and Loctite® 263* was previously shipped to dealers. Additional jam nuts may be ordered from American Isuzu Parts Distribution Network (AIPDN). Please refer to your “involved vehicles listing” before ordering parts. Normal (non-emergency) orders should be placed on a Stock Order. In an emergency situation, parts should be ordered on a VOR (Vehicle Off Road) Order.

Parts Distribution Network (AIPDN). Please refer to your “involved vehicles listing” before ordering parts. Normal (non-emergency) orders should be placed on a Stock Order. In an emergency situation, parts should be ordered on a VOR (Vehicle Off Road) Order.

Additional Loctite® 263 may be sourced locally. One bottle of Loctite® is able to service approximately 40 vehicles.

| Description | QTY | Required | Part Number |

|---|---|---|---|

| JAM NUT | 2 | Required | 8-97556-008-0 |

| STOP BOLT; ADAPTER | 1** | **As Necessary | 2-90KT0-001-0 |

*Loctite® 263 should be utilized within thirty (30) days of first opening the container. Make sure to keep the cap on any time it is not actually being applied. Store in a cool, dry location out of direct sunlight.

SERVICE PROCEDURE

- Apply the parking brake and block the rear wheels.

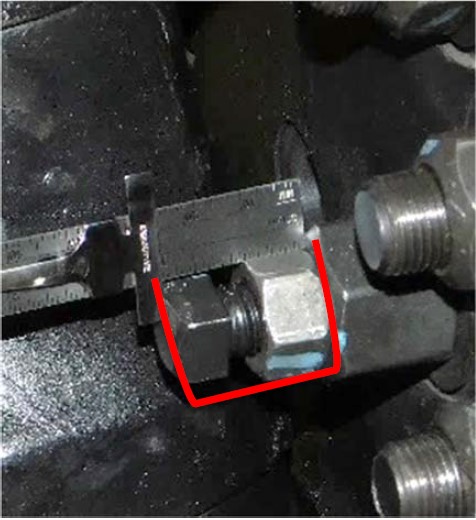

- Start the engine and turn the steering wheel all the way to the left in order to access the right (passenger side) stop bolt. (See Figures 1 and 2.) Shut the engine off after turning the steering wheel.

|  |

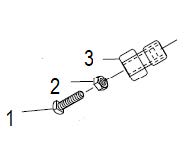

| Figure 1 – Right Front Stop Bolt Assembly | Figure 2 – Stop Bolt Assembly

1. Stop Bolt |

- Use an engineer’s ruler to measure the distance that the stop bolt protrudes out from the adaptor base. (See Figure 3.) Record this measurement.

- Use a ¾” open end wrench to loosen the jam nut, then remove the stop bolt and jam nut from the adaptor base. Remove the jam nut from the stop bolt. Discard the jam nut.

- Use a wire brush and brake cleaner to thoroughly clean the stop bolt threads. Using brake cleaner and a shop towel clean the inside threads of the adaptor base.

- Apply Loctite® 263 to the entire length of the stop bolt threads. (See Figure 4.) IMPORTANT: The Loctite® will start to set within 30 minutes.

- Clean the new Grade 8 jam nut with brake cleaner and a clean shop towel, install it on the stop bolt and thread the stop bolt back into the adaptor base.

- Slightly hand tighten the jam nut to the adaptor. (See Figure 5.) Adjust the stop bolt until it is the same distance from the adaptor base measured and recorded in Step 3 (use a ½” open end wrench as necessary). Using a ¾” deep well socket and a torque wrench, tighten the jam nut to the specified torque. (See Figure 6.) Tightening Torque: 128 N•m (94 lb ft).

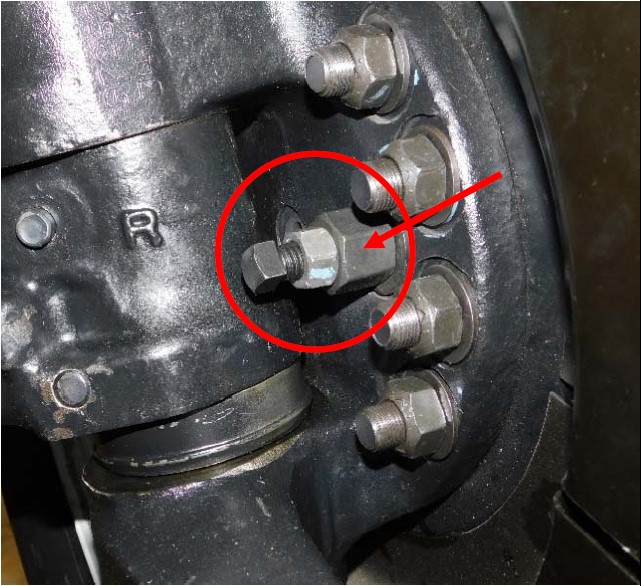

- Start the engine and turn the steering wheel all the way to the right in order to access the left (driver side) stop bolt. (See Figure 1.) Shut the engine off after turning the steering wheel.

- Inspect the stop bolt jam nut to determine whether (a) it is loose (i.e., if you can turn the stop bolt and jam nut by hand) or, worse, (b) the stop bolt has backed out of position, become bent or missing completely. See Figure 7. If the jam nut is loose or in any other worse condition, print the template on the next page for the steering bolt adjustment, and proceed directly to Step 11 in this procedure to replace the stop bolt adapter assembly. If the stop bolt and the jam nut are in place and tight, go to Step 3 and repeat this service procedure through Step 8 for the left (driver) side. Once both sides have been completed, proceed to Step 26.

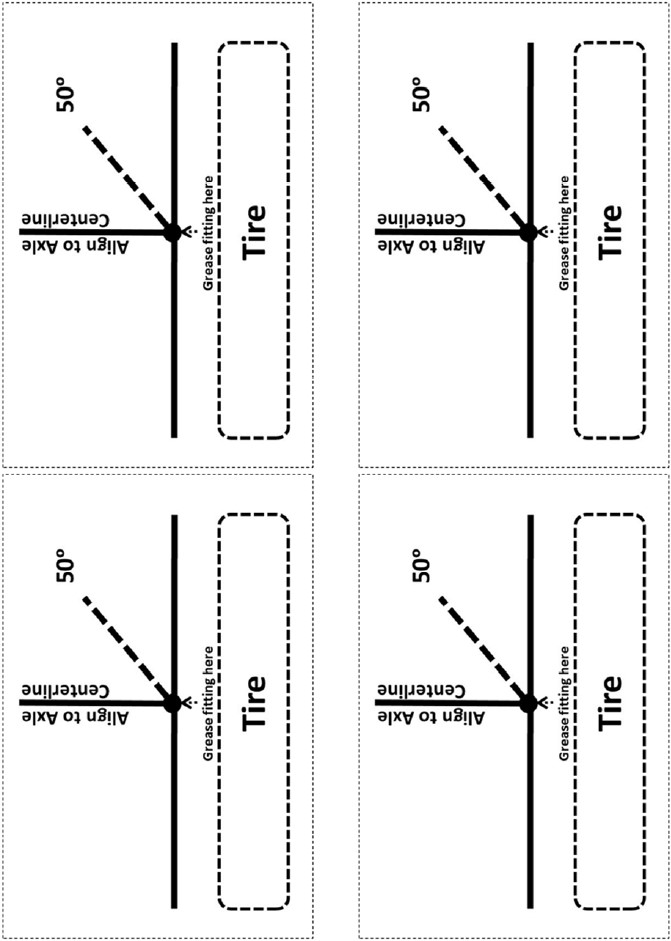

Print the template for the steering bolt adjustment. Cut out one template for use. The remaining templates may be used on future applications.

TEMPLATE FOR STEERING BOLT ADJUSTMENT

- Per the instructions in the applicable Work Shop Manual (WSM), safely tilt the cab and install the safety lock pin.

- Press the template over the left (driver side) upper kingpin grease fitting at the mark indicated. Orientate the template as shown in Figure 8. Make sure the area on the template marked “Tire” is parallel with the tire as shown.

- Start the engine and turn the steering wheel in order to access the left (driver side) stop bolt assembly. Turn off the engine.

- Remove the stop bolt assembly using a 1” deep well socket. Discard the old stop bolt assembly.

- Disassemble the new stop bolt assembly. The new stop bolt assembly (Part No. 2-90KT0001-0) has been fitted with a new Grade 8 nut as indicated with a paint mark. (See Figure 9).

- Disassemble and clean the new adaptor, stop bolt, and jam nut with brake cleaner. Wipe dry with a clean shop towel or rag.

- Install the new stop bolt assembly adaptor base (without the stop bolt or jam nut) using a 1” deep well socket. (See Figure 10.) Tighten the adaptor to the specified torque.

Tightening Torque: 133 N•m (98 lb ft).

- Apply Loctite® 263 to the entire length of the new stop bolt threads. (See Figure 11.)

IMPORTANT: The Loctite® will start to set within 30 minutes of application. Complete all the adjustment and torqueing procedures immediately.

- Install a new jam nut all the way onto the stop bolt.

- Thread the stop bolt all the way into the adaptor that was installed in Step 18. Only tighten hand tight.

- Start the engine and turn the steering wheel in the opposite direction of the wheel/stop bolt being replaced. Continue to turn the steering wheel until the template installed in Step 12 is the same as in Figure 12. The 50° dashed line on the template should align parallel with the casting mark through the center of the axle.

- Using a ½” open-end wrench, adjust the stop bolt until the stop bolt contacts firmly against the axle bolt stop. (See Figure 13.) Ensure the template is still in the position shown in Figure 12.

- Tighten the stop bolt jam nut with a ¾” open-end wrench. Have a second person start the engine and turn the steering wheel in the opposite direction to access the steering stop. Turn off the engine. Use a ¾” deep well socket and a torque wrench to tighten the stop bolt jam nut to the specified torque. (See Figure 14.) Tightening Torque: 128 N•m (94 lb ft).

- Remove the template from the kingpin grease fitting and discard.

- Per the instructions in the applicable WSM, remove and properly stow the safety lock pin and tilt the cab back down. Ensure the cab is locked into place.

IMPORTANT: Allow the Loctite® 263 to dry for at least two (2) hours before delivering or returning the vehicle to the customer.

- Proceed to Applying the Campaign Label.

APPLYING THE CAMPAIGN LABEL

- Using a ball-point pen, fill in a campaign label (Part No. 2-90028-700-0) with Campaign Number 19V-467 (US) or 2019-306 (Canada), Isuzu

dealer code, and repair date.

dealer code, and repair date. - Affix the campaign label onto the driver’s side B-pillar.

CLAIM INFORMATION

Refer to the Isuzu ICS Claims Processing Manual for details on Campaign Claim Submission.

ICS Claims Processing Manual for details on Campaign Claim Submission.

Submit only one claim as indicated below. The initial shipment of the Loctite® and jam nuts may be reimbursed in the sublet allowance.

NOTE: It is not necessary to open a TAL case or generate a health report in order to submit a warranty claim.

| Labor Code | Description | Labor Hours | Sublet Allowance |

|---|---|---|---|

| V1902 | Replace Steering Stop Jam Nuts Only

ADD: Replace Left Side Stop Bolt and Adapter | 0.5

0.4 | $3.00 |

*Includes 0.1 hours for administrative allowance

DEALER RESPONSIBILTY

Dealers are to service all vehicles subject to this program at no charge to customers, regardless of mileage, age of the vehicle, or ownership. Customers who have recently purchased vehicles sold from your vehicle inventory, and for which there is no customer information indicated on the dealer listing, are to be contacted by the dealer. Arrangements are to be made to make the required correction according to the instructions contained in this bulletin. A copy of the customer letter is provided in this bulletin for your use in contacting customers. Program followup cards should not be used for this purpose, since the customers may not as yet have received the notification letter.

In summary, whenever a vehicle subject to this program enters your vehicle inventory, or is in your dealership for service, you must take the steps necessary to ensure the recall remedy has been implemented before selling or releasing the vehicle.

Important:

As required by Federal law, dealers are not to deliver any new vehicle in their inventory, which is covered by a Safety Recall, until the necessary remedy has been performed.

Dealers are to confirm vehicle eligibility prior to beginning repairs by using the Isuzu Vehicle Inquiry Systems (IVIS). Not all vehicles may be involved.

Vehicle Inquiry Systems (IVIS). Not all vehicles may be involved.

For dealers with involved vehicles, a listing of involved vehicles containing the complete vehicle identification number has been or will be provided. Dealers will not have a report available if they have no involved vehicles currently assigned.

OWNER NOTIFICATION

Notification letters will be sent to owners of affected vehicles already retailed in the United States and Canada (see enclosed copies).

[SAMPLE OWNER LETTER – US]

IMPORTANT SAFETY RECALL

NHTSA Recall 19V-467

This notice applies to your vehicle, <VIN>

JULY 2019 Dear Customer,

This notice is being sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. Your vehicle <VIN> <MY> model year Isuzu <SERIES> is involved in safety recall 19V-467.

<SERIES> is involved in safety recall 19V-467.

WHAT IS THE CONDITION?

Isuzu Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in certain 2018, 2019 and 2020 model year FTR vehicles. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in certain 2018, 2019 and 2020 model year FTR vehicles. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

WHAT WE WILL DO

Isuzu dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

WHAT YOU SHOULD DO

We recommend that you contact your Isuzu dealer to schedule an appointment. Although not necessary, please present this Owner Notification Letter at the time of your appointment or refer to Campaign Service Bulletin CB19-E-001. Isuzu

dealer to schedule an appointment. Although not necessary, please present this Owner Notification Letter at the time of your appointment or refer to Campaign Service Bulletin CB19-E-001. Isuzu estimates that the repair may take up to 1½ hours to perform, but additional time may be necessary. To locate the nearest Isuzu

estimates that the repair may take up to 1½ hours to perform, but additional time may be necessary. To locate the nearest Isuzu dealer you can visit our website at www.isuzucv.com, click on the dealer locator link and enter your zip code or state. If you do not have access to a computer terminal please contact our Customer Relations Department at the number listed below.

dealer you can visit our website at www.isuzucv.com, click on the dealer locator link and enter your zip code or state. If you do not have access to a computer terminal please contact our Customer Relations Department at the number listed below.

Isuzu Commercial Truck of America

Commercial Truck of America

Customer Relations

1-866-441-9638

If you have any difficulty having this recall performed, we recommend that you call Isuzu customer relations at 1-866-441-9638. If you are still not satisfied that we have remedied this situation without charge, and within a reasonable amount of time, you may wish to write to the Administrator of the National Highway Traffic Safety Administration, 1200 New Jersey Avenue, SE, Washington DC 20590, or call the agency’s toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov. We regret any inconvenience which this action may cause you.

customer relations at 1-866-441-9638. If you are still not satisfied that we have remedied this situation without charge, and within a reasonable amount of time, you may wish to write to the Administrator of the National Highway Traffic Safety Administration, 1200 New Jersey Avenue, SE, Washington DC 20590, or call the agency’s toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov. We regret any inconvenience which this action may cause you.

Sincerely,

Isuzu Commercial Truck of America, Inc.

Commercial Truck of America, Inc.

Important: If you have sold or traded your Isuzu vehicle, please enter the owner’s name and address, if known, on the attached “Change of Information” postcard, tear off at both perforations, and drop it in the mail. Postage has already been paid. We will contact the new owner.

vehicle, please enter the owner’s name and address, if known, on the attached “Change of Information” postcard, tear off at both perforations, and drop it in the mail. Postage has already been paid. We will contact the new owner.

Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days. Lessor means a person or entity that is the owner, as reflected on the vehicle title, of any five or more leased vehicles.

[SAMPLE OWNER LETTER – CANADA]

IMPORTANT SAFETY RECALL

This notice applies to your vehicle, <VIN>

JULY 2019

Dear Customer,

This notice is sent to you in accordance with the requirements of the Canada Motor Vehicle Safety Act. Your vehicle <VIN> <MY> model year <MAKE>, <SERIES> is involved in safety recall Transport Canada #2019306 (NHTSA 19V-467).

WHAT IS THE CONDITION?

Isuzu Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in certain 2018, 2019 and 2020 model year FTR vehicles. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in certain 2018, 2019 and 2020 model year FTR vehicles. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

WHAT WE WILL DO

Isuzu dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

WHAT YOU SHOULD DO

We recommend that you contact your Isuzu dealer to schedule an appointment. Although not necessary, please present this Owner Notification Letter at the time of your appointment or refer to Campaign Service Bulletin CB19-E-001. Isuzu

dealer to schedule an appointment. Although not necessary, please present this Owner Notification Letter at the time of your appointment or refer to Campaign Service Bulletin CB19-E-001. Isuzu estimates that the repair may take up to 1½ hours to perform, but additional time may be necessary. To locate the nearest Isuzu

estimates that the repair may take up to 1½ hours to perform, but additional time may be necessary. To locate the nearest Isuzu dealer you can visit our website at www.isuzutruck.ca or contact our Customer Relations Department at the number listed below.

dealer you can visit our website at www.isuzutruck.ca or contact our Customer Relations Department at the number listed below.

Isuzu Commercial Truck of Canada

Commercial Truck of Canada

Customer Relations

1-866-441-9638

If you have questions or concerns that your Isuzu dealer is unable to answer, please contact our Customer Relations Department at 1-866-441-9638.

dealer is unable to answer, please contact our Customer Relations Department at 1-866-441-9638.

We regret any inconvenience which this action may cause you.

Sincerely,

Isuzu Commercial Truck of Canada, Inc.

Commercial Truck of Canada, Inc.

Important: If you have sold or traded your Isuzu vehicle, please enter the owner’s name and address, if known, on the attached “Change of Information” postcard, tear off at both perforations, and drop it in the mail. Postage has already been paid. We will contact the new owner.

vehicle, please enter the owner’s name and address, if known, on the attached “Change of Information” postcard, tear off at both perforations, and drop it in the mail. Postage has already been paid. We will contact the new owner.

Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days. Lessor means a person or entity that is the owner, as reflected on the vehicle title, of any five or more leased vehicles.

JULY 2019

Safety Recall 19V-467

Campaign Bulletin CB19-E-001

IMPORTANT SAFETY RECALL

FTR STEERING STOP JAM NUT REPLACEMENT – 19V-467

(Transport Canada 2019-306)

To: Isuzu Commercial Truck Service Managers and Parts Managers

Commercial Truck Service Managers and Parts Managers

This notice and Safety Recall bulletin CB19-E-001 with sample owner letters, are being sent to update you about Safety Recall – FTR Steering Stop Jam Nut Replacement in certain Isuzu commercial vehicles.

commercial vehicles.

AFFECTED VEHICLES

- 2018-2020MY Isuzu

FTR Vehicles Wholesaled Before June 19, 2019

FTR Vehicles Wholesaled Before June 19, 2019

WHAT IS THE CONDITION?

Isuzu Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in 2018, 2019 and 2020 model year FTR vehicles wholesaled before June 19, 2019. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in 2018, 2019 and 2020 model year FTR vehicles wholesaled before June 19, 2019. The jam nut for the steering stopper bolt on the left-front knuckle may loosen and allow the bolt to back away from the steering knuckle. This could result in an increase in the turning radius of the vehicle in left turns. A change in turning radius could make it difficult to make sharp turns. If the vehicle’s turning radius is increased, there is an increased risk of a crash.

CORRECTION

Isuzu dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

dealers will replace the existing left and right jam nuts with a Grade 8 jam nut, torque the nut to a new torque specification and apply Loctite to the nut and bolt. Where a bolt is damaged or missing the assembly will be replaced along with a Grade 8 jam nut. This service will be performed free of charge.

VEHICLES INVOLVED

Involved are 2018, 2019 and 2020 model year FTR vehicles wholesaled before June 19, 2019.

OWNER NOTIFICATION

OWNER NOTIFICATION WILL BEGIN JULY 19, 2019.

Please ensure that all appropriate personnel within your dealership are aware of this Safety Recall –FTR Steering Stop Jam Nut Replacement and that the necessary repairs are performed on all affected vehicles in your inventory per the above instructions.

Isuzu Commercial Truck of America, Inc.

Commercial Truck of America, Inc.

Customer Relations Department

1400 S. Douglass Road, Suite 100, Anaheim, CA 92806 *1-866-441-9638

Chronology of Defect / Noncompliance Determination

573.6 (c) (6) (7)

| Describe the chronology of events leading up to the defect decision or test data for the noncompliance decision: (2000) |

Isuzu received an initial warranty claim of a loose steering stopper bolt in mid‐January 2018. The claim reported difficulty in turning the steering wheel fully to the left. It was determined that the torque wrench being used at the axle production facility was not set up to record or track torque. Isuzu received an initial warranty claim of a loose steering stopper bolt in mid‐January 2018. The claim reported difficulty in turning the steering wheel fully to the left. It was determined that the torque wrench being used at the axle production facility was not set up to record or track torque. Isuzu placed the issue in a “monitor” status and the supplier implemented procedures to record and to track torque. placed the issue in a “monitor” status and the supplier implemented procedures to record and to track torque.

Isuzu Isuzu countermeasures that had been implemented by the supplier. In response, Isuzu In May, Isuzu |

6 Affected Products

Vehicles

16 Associated Documents

Owner Notification Letter(Part 577)

RCONL-19V467-0093.pdf 250.004KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V467-1652.pdf 619.426KB

To View or Download this Document Click Here

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-19V467-3304.pdf 148.507KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)- Stop Delivery Notice

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V467-6603.pdf 835.669KB

Loading...

Loading...

Miscellaneous Document- Supplemental Chronology

RMISC-19V467-6396.pdf 130.219KB

Loading...

Loading...

Recall 573 Report- Amendment 1

RCLRPT-19V467-7784.PDF 215.101KB

Loading...

Loading...

Recall Acknowledgement

RCAK-19V467-4760.pdf 244.864KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-19V467-2624.PDF 215.032KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)- Frequently Asked Questions

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)- Frequently Asked Questions and Answers

Loading...

Loading...

Recall Quarterly Report #2, 2019-4

RCLQRT-19V467-0025.PDF 211.251KB

Loading...

Loading...

Recall Quarterly Report #1, 2019-3

RCLQRT-19V467-7310.PDF 211.144KB

Loading...

Loading...

Latest Recalls Documents

- PRECISION - Ships pre-calibrated to +/- 4% accuracy and ready to use. Include calibration certificate with traceable serial number.

- DURABLE - Reinforced ratchet gear head constructed from hardened, heat treated Chrome Vanadium alloy steel.

- LONG-LASTING - Rust & corrosion protection with our unique and newly invented Electro-Black finish treatment.

- PERFORMANCE - Features an easy-to-read, highlighted yellow print dual-range scale. Identify the markings even in low-light conditions.

- COMFORTABLE - Comes with a reversible ratchet head that drives in both directions and measure torque in a clockwise direction.

- Includes 1-pc. 3/8 in. drive torque wrench; Storage case; Product manual with torque conversion chart

- Wrench emits a click that can be heard and felt when the preset value is reached

- Permanently marked, high-contrast dual-range scale is easy to read, even in low light

- Reversible ratchet head drives in both directions and measures torque in clockwise direction

- Durable all-steel construction has no plastic parts to break or wear out

- High Precision and Quick Reading: 3/8 torque wrench has high contrast and dual range scale( 5-45 Ft-Lb/6.8-61 Nm),making it clear and easy to read. We have professional torque wrench production technology, and after 20000 tests, the calibration error range of the torque wrench is around 3%, making it an essential helper for you

- Safe and Reliable Operation: Equipped with a bidirectional drive ratchet head, torque can be measured clockwise or counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque

- Good Quality and Durable Material: Made of hardened chromium vanadium steel alloy (Cr-V). At the same time, the bottom buckle tail plug adopts a red anodizing process to improve the product's oxidation resistance during use and enhance surface wear resistance. 72 tooth ratchet head, made of chromium molybdenum steel.We use the quality materials which are resist corrosion and are durable

- Quick Torque Setting: Simple and fast torque setting, pull down the locking knob and hold it down to rotate to the torque you need. Release the hand and the locking knob will automatically rebound to lock the torque value. And the designer referred to the appearance of the flashlight handle and designed a non slip and labor-saving knurled handle, making it more comfortable and easy to hold when using

- Easy to Store and Widely Use: You will receive the 3/8-inch drive click torque wrench with a sturdy plastic shell storage box, which is very delicate and durable. Torque wrench is suitable nuts and bolts on various occasions, such as bike, motorcycle, car spark, and torque wrench is suitable for repairing cars and motorcycles, which are essential maintenance tools for car owners

- Portability: durable case for portability or storage

- Added comfort: bi-material handle for comfort and grip

- Hassle free use: locking feature adjusts quick and easily for hassle free use

- Quick identification: scales stamped into housing showing inch and metric torque setting

- Meets or exceeds ASME specifications

- Durable Ratchet Head: Made from Hardened treated Chrome Vanadium steel alloy (Cr-V) Corrosion-Retardant: Satin Finish. Made in Taiwan

- Easy Storage: A sturdy plastic storage case is included. Non-Slip Grip: Knurled handle

- Easy to Read: High Contrast & Dual Range Scale. Accurate: Pre-Calibrated to ± 4%

- Accessories included: 1/2" Drive 5" long Extension Bar

- Simple and Reliable: “Click” sound tells the preset torque value is reached. Stop applying force when you hear and feel it.

- HEAVY-DUTY PERFORMANCE: Handle a wide range of torque applications with precision using the 35-200 in.-lb/3.95-22.5 Nm range of this heavy-duty torque wrench

- DURABLE CONSTRUCTION: Engineered with a hardened treated Cr-V steel alloy ratchet head, this torque wrench provides long-lasting durability with resistance to rust and corrosion

- EASY TO READ SCALE: This adjustable torque wrench features a high contrast, dual range scale pre-calibrated to an accuracy of ± 4% for reliable and precise adjustments

- CONVENIENT STORAGE: Comes with a sturdy plastic case, making it easy to store and transport your 1/4 inch torque wrench safely and conveniently

- USER-FRIENDLY DESIGN: This tork wrench offers easy operation; unlock before adjusting torque value and lock after for stable use; adjust to lowest value and loosen locking ring post-use

- 【8-in-1 Torque Wrench Set】 Includes 1/4, 3/8, 1/2 inch drive torque wrenches that meet your different needs. 5Pcs Adapter: 1/4"Extension bar(4''), 3/8"Extension bar(6''), 1/2"Extension bar(5''), 3/8" Universal Joint, 1/2" to 3/8" Adapter with a sturdy plastic case for storage and portability

- 【Dual range scale & High Precision】 1/4 inch 10-220in.lb/1-24.7Nm with 1 in.lb micro-adjustment, 3/8 inch 10-45ft.lb/13.6-61Nm with 0.25 ft.lb micro-adjustment, 1/2 inch 10-160ft.lb/10-227Nm with 1 ft. lb micro-adjustment. Each wrench undergoes strict and specialized instrument testing before leaving the factory to ensure accuracy within ±3% and is provided with a formal calibration certificate

- 【Safe & Reliable】 This torque wrench set has been upgraded to have a louder "Click" sound, ensuring a clear and stronger click sound when the torque value exceeds 5 Nm, subtler click at lower than 5 Nm. The distinct click sound indicates that the preset torque has been reached, signaling you to stop applying force

- 【Releasable & Dual Direction】These torque wrenches has a quick release button with which accessories can easily be installed and removed, the accessories can grip and is not easy to fall down. With 72-tooth reversible ratchet head, it can be used in both clockwise and counterclockwise directions

- 【High Quality and Durable】 The torque wrench ratchet head is made from hardened treated Cr-Mo Steel for longevity. Handle crafted from high-grade aerospace aluminum for durability, and corrosion resistance. All adapters are treated with phosphating, with stronger wear resistance and a longer lifespan

- ±3% HIGH PRECISION AND COOL APPEARANCE: 1/2 inch drive torque wrench (10-170ft.-lb/13.6-230.5Nm)has a calibration error range of ±3%, high precision, and comes with a corresponding serial number, which is easy to trace the original data, and you can use it with confidence.Hairich torque wrench not only has superior quality but also has a superior appearance. The classic combination of black and red is fashionable and textured, allowing you to enjoy a visual feast during use.

- PREMIUM MATERIAL AND DURABLE: Experience the ultimate durability and antiskid with the torque wrench. The main body of Hairich torque wrench set is made of chrome vanadium steel alloy, which is more strong and more durable. The head of the inch-pound torque wrench adopts a ratchet design with a reversing device to improve work efficiency. The square knurled handle is made of aluminum titanium alloy, which is ergonomic and comfortable to hold for long-time use.

- DUAL SCALE AND QUICK SETTING: Laser Printed by dual-range(ft-lb and Nm). Our professional torque wrench is easy to read and provides direct unit conversion, When the set torque value is reached, the torque wrench will make an audible and felt click to remind you to stop applying force. Pull down the lock knob and hold it until the torque setting is completed. Release the hand, and the lock knob will automatically rebound back to lock the value.

- ERGONOMIC DESIGN AND POWERFUL: Every design of our industrial torque wrench conforms to ergonomic, easy to handle.72-tooth ratchet, 5° ratcheting arc head, a quick-release button for easy loading and unloading, and an aluminum non-slip handle for excellent grip and control. A recent research review that, 72-tooth ratchets are very professional tooth ratchets, you just only rotate 5 degrees to finish it. Not easy to slip and wear, can be used in small spaces, and is more durable and powerful.

- EASY OPERATION AND SAFETY: Thanks to its bidirectional drive ratchet head, our torque wrench can be measured both clockwise and counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque. Notice: At low Nm settings under 5 Nm the "click" sound can be too light to hear.

- 3Pcs Torque Wrench Set: The calibration error range is around 3%, each torque wrench has a calibration certificate. The 3-in-1 torque wrench set can meet your different needs. Including 1/4 inch 20-240 in.lb, 3/8 inch 5-45 ft.lb, 1/2 inch 20-160 ft.lb.

- Safe and Reliable: When the 1/2 torque wrench reaches the preset torque value, it makes a clear "click" sound, accompanied by an obvious hand vibration that reminds you no longer to apply force, prevent damage caused. 72-tooth reversible ratchet head, it can be used both clockwise and counterclockwise directions.

- Quick Release Button: This 3/8 torque wrench has a quick release button with which accessories can easily be installed and removed, the accessories can grip and is not easy to fall down. It is more convenient to use. The torque wrench is made of CR-MO with a higher hardness.

- Easy to Set: First pull down the locking knob and hold it down and then start setting the desired torque value. Release the hand and the locking knob will automatically rebound to lock the torque value. If you do not use, please set the torque key to the minimal torque value.

- Widely Use: The torque wrenches can satisfy you in bicycle, motorcycle, car, truck and wheel screws, wheel nuts and in the device installation, electrical engineering, etc. We insist on bringing customers a good shopping experience.

- 🔧【𝐌𝐢𝐥𝐢𝐭𝐚𝐫𝐲-𝐠𝐫𝐚𝐝𝐞 𝐒𝐭𝐞𝐞𝐥】ETOOLAB torque wrench utilizes military-grade steel as its base material, coupled with professional surface rust protection methods tailored to usage habits. While ensuring user comfort, it enhances product strength, wear resistance, and rust resistance. offers a more comfortable experience and a longer lifespan!

- ⚙️【±𝟑% 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 & 𝐒𝐢𝐦𝐩𝐥𝐞 𝐋𝐨𝐜𝐤𝐢𝐧𝐠 𝐑𝐢𝐧𝐠】Our torque wrench 3/8 drive meets the high precision standard of ±3% and comes with a traceable serial certificate. You can use it with confidence! Moreover, its graduation ring is tightly locked, with smaller incremental values, ensuring precise and consistent torque output even after multiple uses. This reduces the hassle of frequent adjustments. It is undoubtedly an excellent tool for your work!

- 👍【𝐄𝐚𝐬𝐲-𝐭𝐨-𝐑𝐞𝐚𝐝】The scale of this 3/8 drive torque wrench is laser-engraved, using a black background with white markings. dinamometrica de 3/8 ensures clear and easy readability of the scale, even in sunlight. With a dual-scale design, users can conveniently read torque values in two different units according to their preferences, without the need for conversion!

- 🔊【𝐋𝐨𝐮𝐝 𝐂𝐥𝐢𝐜𝐤 𝐒𝐨𝐮𝐧𝐝】This torque wrenches has been upgraded to have a louder "Click" sound. We conducted over 25,000 tests to ensure that each product produces a click sound volume of no less than 45dB when the torque value exceeds 34 lbf·ft. When you hear the distinct click sound, it indicates that the preset torque has been reached, signaling you to stop applying force. You no longer need to worry about damaging your mechanical components.

- 💯【𝐔𝐬𝐞𝐫-𝐅𝐫𝐢𝐞𝐧𝐝𝐥𝐲】Our torque wrench set features a 72-tooth dual-directional ratchet head, allowing for easy operation in both clockwise and counterclockwise directions. It is designed with an adjustable locking ring, making it effortless to adjust the preset torque value.

Last update on 2025-05-09 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.