| “This site contains affiliate links for which OEMDTC may be compensated” |

April 13, 2018 NHTSA CAMPAIGN NUMBER: 18V235000

If the brake switch and nylon retainer are not properly secured, the switch can detach from the bracket causing the brake lights to illuminate whether or not brake pedal is depressed, the shift interlock will not operate and the accelerator pedal input will be disabled resulting in the inability to accelerate. These conditions can increase the risk of a crash.

NHTSA Campaign Number: 18V235

Manufacturer Isuzu Technical Center of America, Inc.

Technical Center of America, Inc.

Components SERVICE BRAKES, HYDRAULIC

Potential Number of Units Affected 80

Summary

Isuzu Technical Center of America, Inc. (Isuzu

Technical Center of America, Inc. (Isuzu ) is recalling certain 2018 Isuzu

) is recalling certain 2018 Isuzu NPR and 2019 Isuzu

NPR and 2019 Isuzu NPR-HD and NPR-XD vehicles. These vehicles have a brake switch and nylon retainer that may not have been properly secured into the steel brake pedal assembly bracket.

NPR-HD and NPR-XD vehicles. These vehicles have a brake switch and nylon retainer that may not have been properly secured into the steel brake pedal assembly bracket.

Remedy

Isuzu has notified owners, and dealers will inspect the seating of the retainer, and re-seat the retainer clip or replace the retainer clip, if necessary, free of charge. The recall began on April 24, 2018. Owners may contact Isuzu

has notified owners, and dealers will inspect the seating of the retainer, and re-seat the retainer clip or replace the retainer clip, if necessary, free of charge. The recall began on April 24, 2018. Owners may contact Isuzu customer service at 1-866-441-9638. Isuzu

customer service at 1-866-441-9638. Isuzu ’s number for this recall is V1801.

’s number for this recall is V1801.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

SAFETY RECALL V1801

BRAKE SWITCH INSPECTION

AFFECTED VEHICLES

- 2018MY Isuzu

NPR Vehicles with 4JJ1 Diesel engines

NPR Vehicles with 4JJ1 Diesel engines - 2019MY Isuzu

NPRHD, NPRXD Vehicles with 4HK1 Diesel Engines

NPRHD, NPRXD Vehicles with 4HK1 Diesel Engines

See the attached VIN list.

INFORMATION

CONDITION

The affected vehicles were equipped with a new brake switch and nylon retainer. In production, the brake switch retainer tabs may not have been fully secured into the steel brake pedal assembly bracket. An unsecured tab could allow the switch and retainer to detach from the bracket. If the switch and retainer become detached, the brake lights will illuminate whether or not the brake pedal is depressed, the shift interlock will not operate and the accelerator pedal input will be disabled, causing the vehicle to lose power and increasing the risk of a crash.

CORRECTION

Isuzu dealers are to inspect and, if necessary, replace the retainer clip to address this concern. This service will be performed free of charge.

dealers are to inspect and, if necessary, replace the retainer clip to address this concern. This service will be performed free of charge.

VEHICLES INVOLVED

Involved are a limited number of Model Year 2018 NPR vehicles with 4JJ1 Diesel engines and 2019 NPRHD, NPRXD (4HK1) Isuzu N-Series vehicles with 4HK1 Diesel engines. See the attached VIN list.

N-Series vehicles with 4HK1 Diesel engines. See the attached VIN list.

Important: Dealers are to confirm vehicle eligibility prior to beginning repairs by using the Isuzu Vehicle Inquiry System (IVIS).

Vehicle Inquiry System (IVIS).

For dealers with involved vehicles, a report of involved vehicles containing the complete vehicle identification number has been or will be provided. Dealers will not have a report available if they have no involved vehicles currently assigned.

PARTS INFORMATION

Dealers with affected vehicles will be shipped replacement retainer clips in order to complete any necessary repairs at no charge. Dealers may submit for a claim for parts mark-up reimbursement as a sublet allowance. See Claim Information for details.

SERVICE PROCEDURE

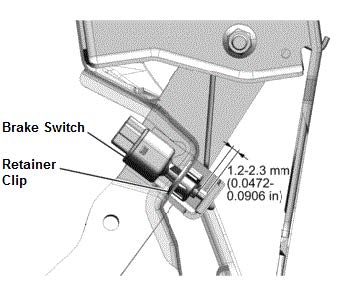

- Locate the brake switch on the front of the brake pedal bracket. (See Figure 1) The brake switch is installed into the retainer clip (See Figure 2) which is installed onto a flat metal plate on the brake pedal bracket. Ensure to properly illuminate the area with a drop light.

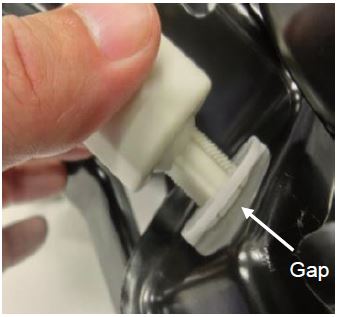

- Push the brake switch towards the passenger side and then towards the driver side (See Figure 3) to determine if the retainer clip lifts up and forms a gap on either side from the flat metal plate (See Figure 4).

a. If the retainer clip does not lift up and form a gap, then the clip is fully seated and the campaign is complete. Proceed to the “Applying the Campaign Label” section.

b. If the retainer clip does lift up and form a gap on either side, proceed to Step 3.

- Remove the brake switch by turning it counter-clockwise until it stops, then pulling it straight out. (See Figures 5 and 6).

Note: There is no need to disconnect the electrical connector.

- Push inward on the retainer clip with a fingertip – an audible click may be heard.

- Reinstall the brake switch by inserting the switch into the retainer clip opening, then push inward until the tip of the threaded portion of the switch makes contact with the pedal side bracket. This will depress the brake switch, but not the brake pedal. Rotate the switch clockwise approximately 45° while contact is being made.

Note: Make sure NOT to depress the pedal with the switch when it makes full contact.

A gap (1.2 to 2.3 mm) between the tip of the threaded portion of the switch and the pedal side bracket will be made automatically when the switch is locked into place by turning. (See Figure 7) This gap is the correct brake switch adjustment.

- Repeat Step 2 to determine if the retainer clip lifts to form a gap. (See Figures 3 and 4)

- If the retainer clip does not lift up and form a gap, then the clip is fully seated and the campaign is complete. Proceed to the “Applying the Campaign Label” section.

- If the retainer clip does lift up and form a gap, proceed to Step 7.

- Remove the two (2) accelerator pedal position sensor assembly nuts and set the assembly off to the side with the electrical connector still connected. (See Figures 8 and 9)

- Remove the brake switch as outlined in Step 3.

- Using a flat-head screwdriver, break off the top round flange of the retainer clip to allow the complete removal of the clip. (See Figures 10 and 11) Carefully inspect the entire area to ensure that any broken pieces of the clip are completely removed and discarded.

- Install the new retainer clip by pushing it firmly in place with a fingertip – an audible click should be heard.

- Reinstall the brake switch as outlined in Step 5.

- Repeat Step 2 to determine if the retainer clip lifts to form a gap. (See Figures 3 and 4) If the retainer clip is still lifting to form a gap, repeat Steps 8 through 11.

- Reinstall the accelerator pedal position sensor assembly with the two (2) nuts removed in Step 7. Ensure that the position sensor arm is correctly located in the opening in the bottom of the accelerator pedal. (See Figure 12)

Tightening Torque: 20 N·m (14 lb·ft)

- Proceed to Applying the Campaign Label.

APPLYING THE CAMPAIGN LABEL

- Using a ball-point pen, fill in a campaign label (Part No. 2-90028-700-0) with Campaign Number (V1801), Isuzu

dealer code, and repair date.

dealer code, and repair date. - Affix the campaign label onto the driver’s side B-pillar.

CLAIM INFORMATION

Submit a Campaign Claim with the information indicated below.

| Labor Code | Description | Labor Hours | Sublet Allowance |

|---|---|---|---|

| V1801 | Brake Switch – Inspection & Repair | 0.4 | $0.65 |

*Includes 0.1 hours for administrative allowance

Refer to the Isuzu ICS Claims Processing Manual for details on Campaign Claim Submission.

ICS Claims Processing Manual for details on Campaign Claim Submission.

DEALER RESPONSIBILTY

Dealers are to service all vehicles subject to this program at no charge to customers, regardless of mileage, age of the vehicle, or ownership. Customers who have recently purchased vehicles sold from your vehicle inventory, and for which there is no customer information indicated on the dealer listing, are to be contacted by the dealer. Arrangements are to be made to make the required correction according to the instructions contained in this bulletin. A copy of the customer letter is provided in this bulletin for your use in contacting customers. Program follow-up cards should not be used for this purpose, since the customers may not as yet have received the notification letter.

In summary, whenever a vehicle subject to this program enters your vehicle inventory, or is in your dealership for service, you must take the steps necessary to be sure the program correction has been made before selling or releasing the vehicle.

Important:

As required by Federal law, dealers are not to deliver any new vehicle in their inventory, which is covered by a Safety Recall, until the necessary remedy has been performed.

Dealers are to confirm vehicle eligibility prior to beginning repairs by using the Isuzu Vehicle Inquiry Systems (IVIS). Not all vehicles may be involved.

Vehicle Inquiry Systems (IVIS). Not all vehicles may be involved.

For dealers with involved vehicles, a listing of involved vehicles containing the complete vehicle identification number has been or will be provided. Dealers will not have a report available if they have no involved vehicles currently assigned.

OWNER NOTIFICATION

A limited number of affected vehicles have already been retailed. Notification letters will be sent to owners of affected vehicles already retailed in the United States and Canada in the near future. A sample copy of the owner letter will be provided to dealers once it has been approved by NHTSA. In the meantime, Isuzu will attempt to inform owners of affected vehicles already retailed of this safety recall by alternative means (for example, by telephone).

will attempt to inform owners of affected vehicles already retailed of this safety recall by alternative means (for example, by telephone).

STOP SALE AND DELIVERY – SAFETY RECALL

Date: April 4, 2018

Subject: Stop Sale and Delivery for Upcoming Safety Recall

Affected Models: See Attached VIN List

To: Isuzu Dealer Principal, Sales Manager and Service Manager

Dealer Principal, Sales Manager and Service Manager

Effective immediately, stop the delivery of the above vehicles in your inventory. Isuzu is in the process of taking steps to address a safety-related defect in these vehicles. Federal law prohibits the sale and delivery to customers of any vehicle containing a safety defect. You must not deliver any covered vehicles to customers until after the vehicle has been remedied.

is in the process of taking steps to address a safety-related defect in these vehicles. Federal law prohibits the sale and delivery to customers of any vehicle containing a safety defect. You must not deliver any covered vehicles to customers until after the vehicle has been remedied.

WHAT IS THE CONDITION?

The affected vehicles were equipped with a new brake switch and nylon retainer. In production, the brake switch retainer tabs may not have been fully secured into the steel brake pedal assembly bracket. An unsecured tab could allow the switch and retainer to detach from the bracket. If the switch and retainer become detached, the brake lights will illuminate whether or not the brake pedal is depressed, the shift interlock will not operate and the accelerator pedal input will be disabled, causing the vehicle to lose power and increasing the risk of a crash.

WHAT WE WILL DO

In the near future, Isuzu will (1) send you replacement retainer clips and (2) release a campaign bulletin with more information and claim submission details.

will (1) send you replacement retainer clips and (2) release a campaign bulletin with more information and claim submission details.

WHAT YOU SHOULD DO

For affected vehicles in dealer inventory, open a repair order referencing this Stop Sale and perform the following inspection to determine whether the retainer clip is or is not properly seated and whether it needs to be replaced. If the clip requires replacing, hold the vehicle until the replacement part is received and can be installed.

INSPECTION

- Push the brake switch towards the passenger side and then towards the driver side. If the nylon retainer lifts up on either side try to re-seat it. To re-seat the retainer, remove the brake switch, and then apply downward force to the retainer by hand. An audible click may be heard.

- Reinstall and adjust the brake switch as per the appropriate Service Manual. Repeat the previous step. This time in addition to pushing, also pull up on the switch. If the retainer lifts up again or the brake switch and retainer come out altogether, the retainer must be replaced.

- If the retaining clip is successfully re-seated, the vehicle has been corrected and may be released for sale. Apply a campaign label indicating the recall inspection and re-seating were completed (referencing labor code V1801) and submit a campaign claim in accordance with the campaign bulletin to be released in the near future.

- If the retainer clip cannot be properly re-seated, it must be replaced. In that case, you must hold the vehicle until you (a) receive a replacement retainer clip and (b) repair the vehicle in accordance with the campaign bulletin to be released in the near future.

We regret any inconvenience which this action may cause you.

Sincerely,

Isuzu Commercial Truck of America, Inc.

Commercial Truck of America, Inc.

ISUZU

IMPORTANT SAFETY RECALL

NHTSA Recall 18V-235

This notice applies to your vehicle,

APRIL 2018

Dear Customer,

This notice is being sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. Your vehicle safety recall 18V-235 (Transport Canada 2018-183).

WHAT IS THE CONDITION?

Isuzu Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in a limited number of model year 2018 NPR vehicles with 4JJ1 diesel engines, and model year 2019 NPRHD, NPRXD vehicles with 4HKI diesel engines. The affected vehicles were equipped with a new brake switch and nylon retainer. In production, the brake switch retainer tabs may not have been fully secured into the steel brake pedal assembly bracket. An unsecured tab could allow the switch and retainer to detach from the bracket. If the switch and retainer become detached, the brake lights will illuminate whether or not the brake pedal is depressed, the shift interlock will not operate and the accelerator pedal input will be disabled, causing the vehicle to lose power and increasing the risk of a crash.

Motors Limited has decided that a defect, which relates to motor vehicle safety, exists in a limited number of model year 2018 NPR vehicles with 4JJ1 diesel engines, and model year 2019 NPRHD, NPRXD vehicles with 4HKI diesel engines. The affected vehicles were equipped with a new brake switch and nylon retainer. In production, the brake switch retainer tabs may not have been fully secured into the steel brake pedal assembly bracket. An unsecured tab could allow the switch and retainer to detach from the bracket. If the switch and retainer become detached, the brake lights will illuminate whether or not the brake pedal is depressed, the shift interlock will not operate and the accelerator pedal input will be disabled, causing the vehicle to lose power and increasing the risk of a crash.

WHAT WE WILL DO

To correct this condition, Isuzu dealers are to inspect the retainer clip and either re-seat (secure) or, if necessary, replace it. This service will be performed free of charge.

dealers are to inspect the retainer clip and either re-seat (secure) or, if necessary, replace it. This service will be performed free of charge.

WHAT YOU SHOULD DO

We recommend that you contact your Isuzu dealer to schedule an appointment. Although not necessary, please present this Owner Notification Letter at the time of your appointment or refer to Campaign Service Bulletin CBI 8-H-OOI. Isuzu

dealer to schedule an appointment. Although not necessary, please present this Owner Notification Letter at the time of your appointment or refer to Campaign Service Bulletin CBI 8-H-OOI. Isuzu estimates that the repair will take approximately 24 minutes to perform, but additional time may be necessary’. To locate the nearest Isuzu

estimates that the repair will take approximately 24 minutes to perform, but additional time may be necessary’. To locate the nearest Isuzu dealer you can visit our website at www.isuzucv.com, click on the dealer locator link and enter your zip code or state. If you do not have access to a computer terminal please contact our Customer Relations Department at the number listed below.

dealer you can visit our website at www.isuzucv.com, click on the dealer locator link and enter your zip code or state. If you do not have access to a computer terminal please contact our Customer Relations Department at the number listed below.

Isuzu Commercial Truck of America

Commercial Truck of America

Customer Relations

1-866-441-9638

If you have any difficulty having this recall performed, we recommend that you call Isuzu customer relations at 1-866-441-9638. If you are still not satisfied that we have remedied this situation without charge, and within a reasonable amount of time, you may wish to write to the Administrator of the National Highway Traffic Safety Administration, 1200 New Jersey Avenue, SE, Washington DC 20590, or call the agency’s toll-free Vehicle safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

customer relations at 1-866-441-9638. If you are still not satisfied that we have remedied this situation without charge, and within a reasonable amount of time, you may wish to write to the Administrator of the National Highway Traffic Safety Administration, 1200 New Jersey Avenue, SE, Washington DC 20590, or call the agency’s toll-free Vehicle safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

We regret any inconvenience which this action may cause you.

Sincerely,

Isuzu Commercial Truck of America, Inc.

Commercial Truck of America, Inc.

Important: If you have sold or traded your Isuzu vehicle, please enter the owner’s name and address, if known, on the attached ‘Change of Information” postcard, tear off at both perforations, and drop it in the mail. Postage has already been paid We will contact the new Owner.

vehicle, please enter the owner’s name and address, if known, on the attached ‘Change of Information” postcard, tear off at both perforations, and drop it in the mail. Postage has already been paid We will contact the new Owner.

Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days. Lessor means a person Or entity that is the Owner, as reflected On the vehicle title, Of any five or more leased vehicles.

3 Affected Products

Vehicles

8 Associated Documents

Recall Quarterly Report #3, 2018-4

RCLQRT-18V235-7789.PDF 211.321KB

Loading...

Loading...

Recall Quarterly Report #4, 2019-1

RCLQRT-18V235-4661.PDF 211.42KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Recall Acknowledgement

RCAK-18V235-6194.pdf 246.068KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-18V235-4859.pdf 218.853KB

Loading...

Loading...

Owner Notification Letter(Part 577)

RCONL-18V235-2173.pdf 200.195KB

Loading...

Loading...

Recall Quarterly Report #2, 2018-3

RCLQRT-18V235-2584.PDF 211.235KB

Loading...

Loading...

Latest Recalls Documents

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS, disc and drum brake systems

- Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100 percent longer than DOT 3, 50 percent longer than DOT 4, and 10 percent longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid boiling and vapor lock

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- The 336⁰F wet boil point and 521⁰F dry boil point exceeds common characteristics for DOT 4 brake fluids

- Provides corrosion protection in brake components

- Matches needs of all DOT 4 manufacturer recommendations

- Compatible with all DOT 3 and DOT 4 applications

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

Last update on 2025-05-09 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.